The oil and gas industry plays a pivotal role in powering economies and fueling our modern way of life. At the heart of this industry lies oilfield drilling, a complex and sophisticated process that involves accessing and extracting valuable resources buried deep within the Earth’s crust. Among the critical components driving this process are oilfield drill bits – powerful tools designed to cut through rock formations and reach these hidden reservoirs. In this blog, we will explore five essential things you need to know about oilfield drilling, with a focus on the indispensable role of oilfield drill bits.

1. Exploration and Site Selection:

Oilfield drilling begins with thorough exploration and site selection. Geologists and geophysicists conduct extensive surveys to identify potential oil and gas reserves beneath the Earth’s surface. Advanced technologies, such as seismic imaging and 3D modeling, are used to map subsurface structures and detect potential reservoirs.

Once a promising site is identified, a drilling location is carefully chosen based on geological data, proximity to existing infrastructure, and regulatory considerations. This critical step lays the groundwork for successful drilling operations.

2. Drilling Rig Types:

Drilling rigs are specialized structures that house the equipment required for the drilling process. There are two main types of drilling rigs used in the oil and gas industry:

a. Onshore Drilling Rigs:

Onshore drilling rigs are located on land and are more cost-effective to set up than their offshore counterparts. They are used for drilling wells that originate on land and can be moved from site to site as needed.

b. Offshore Drilling Rigs:

Offshore drilling rigs are situated in bodies of water, such as oceans or seas, and are used to drill wells in underwater locations. They come in various configurations, including fixed platforms, jack-up rigs, semi-submersibles, and drillships, each suited for specific water depths and environmental conditions.

3. The Role of Oilfield Drill Bits:

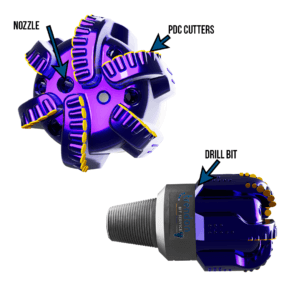

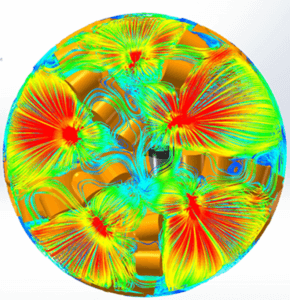

Oilfield drill bits are the workhorses of the drilling process. These robust tools are attached to the bottom of the drill string and are responsible for cutting through rock formations. The drill bits come in various types, such as roller cone bits, PDC bits, and tricone bits, each designed for different geological conditions and drilling scenarios.

As the drill string rotates, the oilfield drill bit grinds and crushes the rock below, creating a borehole that allows access to the oil or gas reservoir. The efficiency and durability of the drill bit are crucial for the success of the drilling operation.

4. The Use of Drilling Fluids:

Drilling fluids, commonly known as “mud,” are an integral part of oilfield drilling. These specialized fluids serve multiple purposes, including:

Cooling and Lubrication:

Drilling generates significant heat due to friction between the drill bit and the rock. Drilling fluids help cool and lubricate the drill bit, preventing overheating and reducing wear.

Rock Cuttings Removal:

As the drill bit cuts through the rock, it generates cuttings that need to be removed from the borehole. Drilling fluids carry these cuttings to the surface, allowing for smooth and continuous drilling.

Wellbore Stability:

Drilling fluids create hydrostatic pressure that counters the natural pressure of the surrounding rock formations, preventing the borehole from collapsing and maintaining wellbore stability.

Formation Evaluation:

The drilling fluids carry valuable information about the subsurface formations. Analysis of the drilling fluids’ properties helps geologists and engineers assess the reservoir’s potential and characteristics.

5. Environmental Considerations:

Oilfield drilling, both onshore and offshore, is subject to strict environmental regulations and considerations. Environmental impact assessments are conducted before drilling operations commence, ensuring that potential risks are identified and mitigated.

Measures are implemented to protect local ecosystems, water sources, and wildlife habitats. Proper disposal and management of drilling fluids and cuttings are essential to prevent pollution and minimize ecological disturbances.

Knowledge is Power

Oilfield drilling is a complex and sophisticated process that involves thorough exploration, well-planned site selection, and the use of specialized drilling equipment like oilfield drill bits. From onshore to offshore drilling, each stage requires precision, expertise, and adherence to environmental regulations. The efficiency and effectiveness of oilfield drill bits are paramount in extracting valuable resources and driving the success of the oil and gas industry. As technology advances, oilfield drilling continues to evolve, ensuring a sustainable and responsible approach to meeting the world’s energy needs.

At Trendon Bit Service Ltd, we supply customers with everything it takes to run a successful drilling operation, right from our headquarters in Calgary, Alberta. We manufacture, supply, and service PDC drill bits, Tricone drill bits, and reamers, so that you can depend on us for everything oil drilling. When it comes to Trendon, we pride ourselves in providing expertly constructed tools that last; our oil drilling bits are the highest quality in the market – and so are our oil rig bit maintenance services., because we want to ensure that your oil drilling bits are kept in top condition. At Trendon Bit Service Ltd, our staff will help you find the best oilfield drilling bits for your project – and fast! For quick, efficient, and expert service, call Trendon at 403-536-2770.